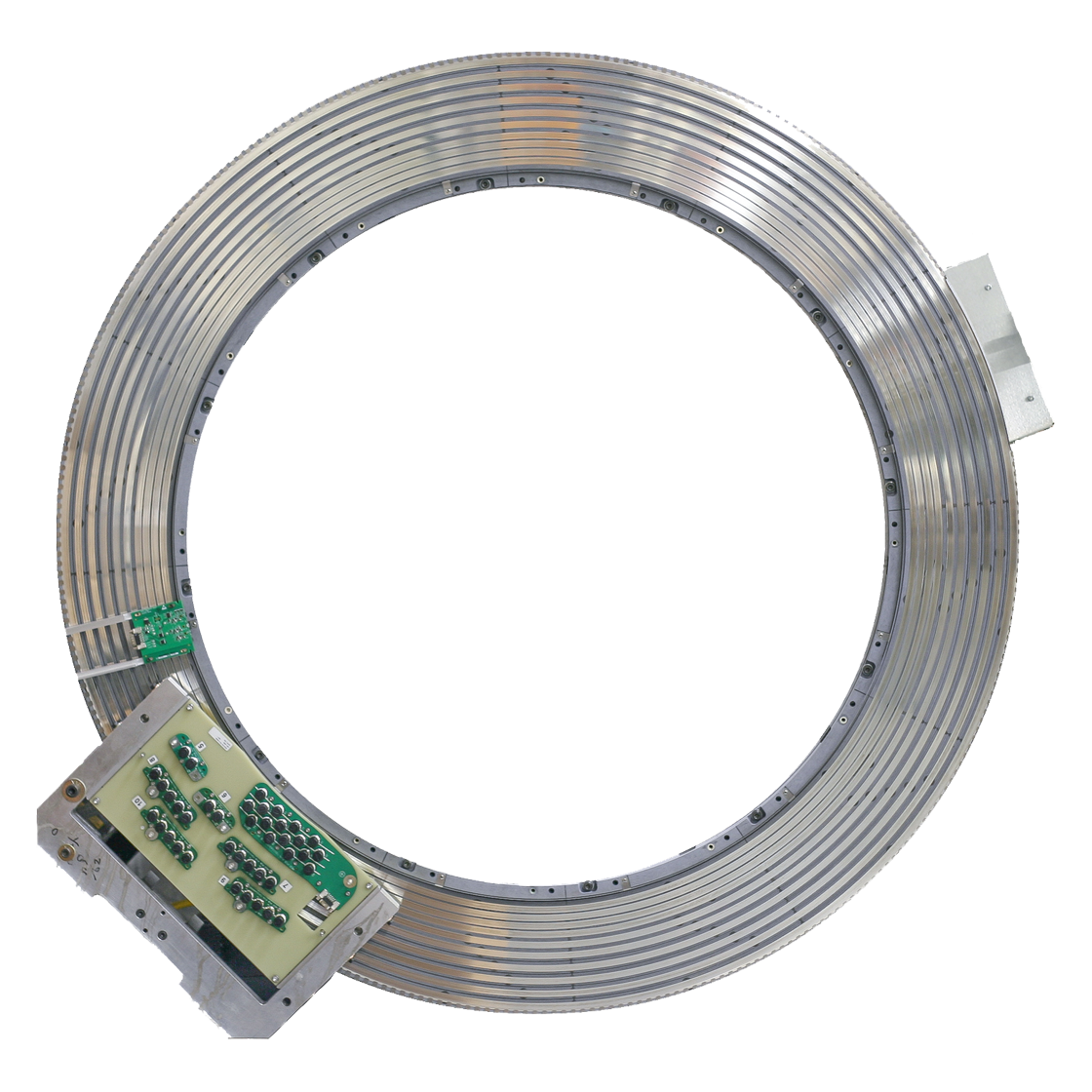

CT Scan Slip Rings

As a world leader in slip ring design and manufacturing, Moog works with many key CT system manufacturers to provide reliable large diameter slip ring solutions.

High Performance

Computed Tomography (CT) scanners place rigorous demands on all of their subsystems and components. The dramatic increase in the functionality of CT, including cardiology, oncology and acute care, places requirements of robust, artifact-free imaging on all elements of the data generation, transmission and processing system.

One of the primary challenges within a CT scanner is the requirement to transmit image data from the rotating x-ray detector array to the stationary data processing computer. In the earliest CT scanners, this data transmission task was accomplished with a slip ring, i.e., sliding electrical contacts. With the ever increasing data speed requirements of multi-slice machines, an alternative method of handling data across the rotating interface is required.

Image Data Transfer Across Slip Rings

Successful image data transfer across a slip ring in helical scan CT machines requires a non-contacting solution. There are two methods used to transfer this data: optical and RF/capacitive coupled data rings.

High Speed Data Link

Moog has developed its patented Optical DataLinkTM to transmit the high rate image data from the Detector Array (DAS) across the rotational interface of the CT gantry.

Large Diameter Slip Rings

Large diameter slip rings represent the union of manufacturing processes and technologies that enable Moog to offer large, high volume slip rings with advanced features that are cost effective.