Key Slip Ring Technology Behind Medical CT Systems

March 15, 2018

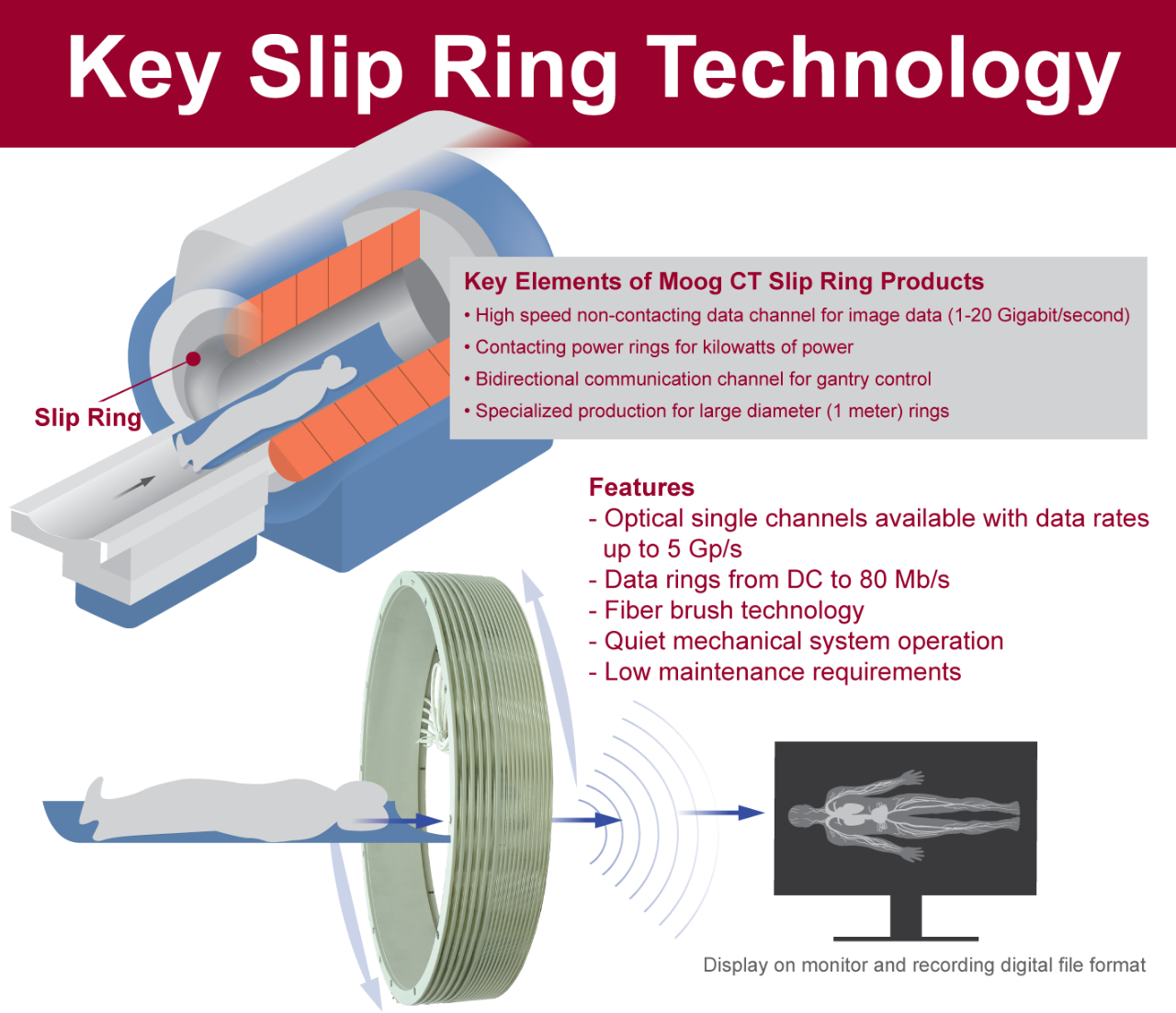

CT scanners operate by rotating an x-ray tube and an x-ray detector array around the patient at rotational speeds of 120-280 RPM. A beam of x-rays is directed through the patient’s body to be captured by the detector array for subsequent image creation. One of the key technologies behind the dramatic improvement in CT performance is slip ring innovation that enables increasingly improved images and diagnostic functionality. As a world leader in slip ring design and manufacturing, Moog works with many key CT system manufacturers to provide reliable large diameter slip ring solutions.

Slip Ring Advantages for Medical Applications

- Fiber brush technology with long maintenance-free life and minimal wear debris

- Low audible noise for overall quieter mechanical system operation

- Options of optically or capacitively coupled channels for high speed data communications

- High circuit density and compact design

- Large bore designs with an inside diameter up to 50 inches (1270 mm)

Error-free transmission of the image data from the x-ray detector array at data speeds of up to and exceeding 20 Gigabit per second is the key element of CT slip ring design. Moog accomplishes this transfer with either optical or capacitive data channels. Electrical power of several kilowatts is transferred across sliding electrical contacts on a one-meter diameter ring at 200+ RPM using patented fiber brush technology.

Key Elements of Moog CT Slip Ring Products

- High speed non-contacting data channel for image data (1-20+ Gigabit/second)

- Contacting power rings for kilowatts of power

- Bidirectional communication channel for gantry control

- Specialized production for large diameter (1 meter) rings

Moog leads the way in developing innovative slip ring designs that improve the diagnostic capability and affordability of medical CT imaging. To learn how our slip rings would fit your application, contact our slip ring experts.

About the Author

Glenn Dorsey is a Product Development Specialist at Moog, working at Moog’s Blacksburg, VA, operations. With 35 years of experience in the field, Glenn helps our customers find the right slip ring and data transfer technology to match their problem solution needs.