Slip Ring Fundamentals

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. Also called a rotary electrical joint, collector or electric swivel, a slip ring can be used in any electromechanical system that requires unrestrained, intermittent or continuous rotation while transmitting power and / or data.

Benefits of Using a Slip Ring

- Improves mechanical performance

- Simplifies system operation

- Eliminates damage-prone wires dangling from movable joints

Basic Slip Ring Configuration

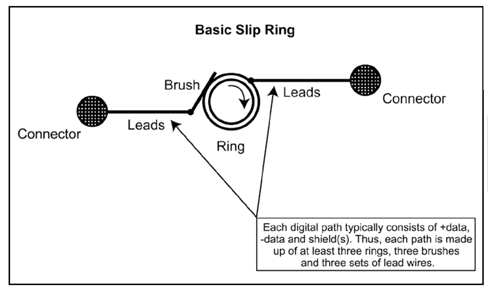

As the world's leading slip ring manufacturer, Moog offers more than 10,000 standard and customizable slip ring designs. Each slip ring has the following basic components:

- Ring

A ring assembly provides one or more circuit paths. Each ring is electrically conductive and provides a circuit path over a full 360 degrees of rotation of the ring assembly.

- Brushes

Brushes provide electrical contact between the rotating (usually the ring) and the stationary parts of the assembly. The brushes ride on the ring, and are mounted in a brush block assembly, usually on the stationary structure.

- Leads

Input and output leads connect the ring and brushes to the outside world.

- Connector

Connectors link to the slip ring assembly wiring. Connectors are optional, and are often specified by the customer.

Specifying a High Performance Slip Ring

The following parameters should be specified to assure satisfactory operation in a specific application:

- Data bus used to transmit data, i.e. Profibus, Ethernet, Firewire

- Cable type used to connect to the slip ring

- Maximum cable length between transmitter and receiver

- Maximum data rate

- Maximum error rate that can be tolerated

- Maximum size, i.e. diameter and length

- Number of circuits and their ratings, i.e. voltage, current

- Maximum operating speed of rotation

- Operating environment

Still have questions about slip rings? Contact a Moog expert.