Mike Ercolano on Electrohydrostatic Actuators

Mike's Background

I graduated from Villanova University with a BS in Mechanical Engineering. After college I worked for a company that built a number of systems that used Moog servovalves as the control element. Those systems taught me about servovalves and helped me get hired into Moog’s new Engine Controls Division which supplied control valves and actuators for commercial and military turbine engines. Since then I have, over the last 30 years, worked in Moog’s Technology Center, Aircraft Group and currently the Space and Defense Group. After starting out designing servovalves, I have designed a variety of control valves and actuators for aerospace applications. For the past fifteen years I have spent most of my time designing electrohydrostatic actuators (EHAs) for aircraft flight controls and more recently launch vehicles. Moog was involved in some early “electric actuation” demonstration programs which included electrohydrostatic, as well as, electromechanical actuators (EMAs). These types of actuators convert electric power directly to linear motion, load and rate, without the need for a centralized hydraulic system in the vehicle. I got involved with designing EHAs for the first military aircraft to go fully electric. I then designed the EHAs used on the flight control system of a commercial airliner and for the past five years I have been working to put the first EHAs on a space launch system.

Intro to EHA's

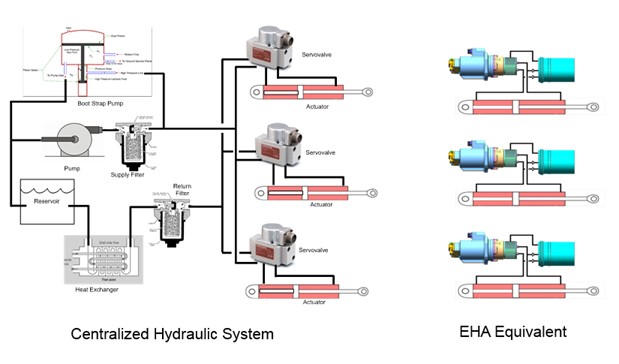

Moog’s EHAs were originally designed to replace conventional electrohydraulic actuators used in an aircraft flight control system. A conventional electrohydraulic actuator is supplied with hydraulic power from a centralized pumping system and controls that power through a servovalve to direct the output piston. An EHA enables the conversion of electric power to be done at the point of the demand. This gives you the advantage of “power on demand” which means you are only drawing power when it is required by the system. This more distributed architecture is different from a centralized system which continually produces power and typically burns off what is unused by turning it into heat. With this change in operation you may be able to reduce the size of the power system needed for an application and eliminate the thermal management of the waste heat produced. Another benefit of the EHA approach is that the actuator is controlled by modulating the speed and direction of the electric motor, eliminating the parasitic power loss of the servovalve which controls a conventional hydraulic actuator. This loss is typically around one third of the supplied power at the actuator’s peak power output. From our customer’s point of view, the EHAs greatly simplify the integration of their system since all the messy hydraulic components are combined into one sealed, easily replaceable unit. This also reduces the skill level required for technicians and maintenance personnel as well as the facilities requirements.

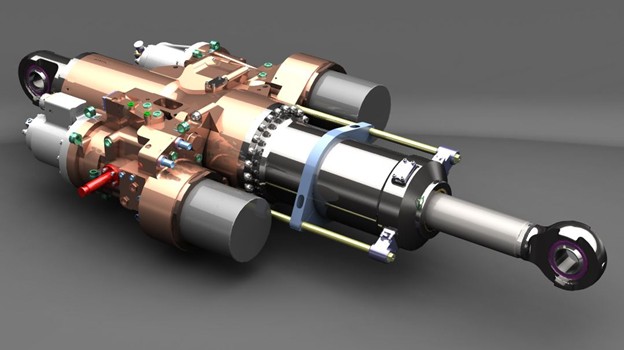

The basic components of the Moog EHA include the traditional piston and cylinder for the mechanical output as would a typical hydraulic actuator but it needs to include a scaled version of the key functions that exist in a centralized system. This is done by combining a fixed displacement, axial piston pump and a brushless DC, three phase motor. The motor is commutated by a controller that is supplied with rotor angle feedback and delivers electric power to achieve the desired motor speed. As is typical with electrohydraulic actuators, a linear variable displacement transducer (LVDT) provides feedback to the position loop in the system.

The EHAs also have a built in pressurized reservoir that maintains sufficient pressure in the system to insure that the pump does not cavitate. The reservoir also manages the expansion and contraction of the hydraulic fluid as the system temperature varies. In order to minimize the size of the reservoir, the internal pressure is typically allowed to rise to hundreds of psi at the high end of the temperature range. This means that for a similar differential pressure across the pump, the maximum design pressure of an EHA will be higher than a centralized hydraulic system where the return pressure might be a maximum of 150 psi. This will drive the design requirement for the pressurized components of the EHA from a typical value of 3000 psi to something closer to 4000 psi. The reservoir system is separated from the load circuit by a pair of anti-cavitation check valves. These valves allow the pump to draw fluid from the reservoir which compensates for the leakage that flows into the reservoir through the pump case. In order to verify the charge level within the EHA, there is typically a pressure transducer and temperature sensor within the reservoir hydraulic circuit that enables the end user to compare the measured pressure at a given temperature with the expected value for a fully charged system.

Besides the basic components discussed already, there are a number of auxiliary components that can be included depending on the needs of an application such as different fail safe modes, service operations or redundancy. Examples of these components are; blocking or bypass valves that control the interconnect between the pump and the cylinder, load relief valves that can protect the actuator and structure from transient disturbances, pressure sensors that can provide load feedback into the system or charging systems that enable in-situ recharging of the EHA.

• Why EHAs?

There are a number of reasons why EHAs might be a preferable solution for an application. As stated earlier, from the customer’s point of view, the ease of integration into the system or vehicle and the simplified maintenance can be very attractive. Also from an overall system reliability point of view, a standalone actuation system that is not dependent on a central hydraulic system can be advantageous, especially where redundancy is a concern. The power on demand mode of operation can provide weight, size and cost advantages if the applications duty cycle demands high performance intermittently.

All of these advantages might also be applied to electromechanical actuators as well but what separates EHAs from EMAs is their ability to be easily configured into fault tolerant designs. Where an EMA can be configured to provide some redundancy in a torque summed, dual motor arrangement, without including a clutch in the gear train, the actuator may have to be sized to drag a shorted motor along while providing the required performance. An EHA by comparison can easily switch from a dual motor operation to a single motor in the event of a failure through a logic valve without having to deal with a parasitic loss resulting from the failed motor. Also, EHAs can easily be configured into different redundancy schemes. In a flow summed design, multiple motor-pump assemblies can provide high rates with full operation and fractional rates but full load in the event of a failure. In a force summed, tandem arrangement the actuator can provide half the load at full rate with one motor failed and has the advantage of providing independent, isolated hydraulic systems.

Beyond the distinctions discussed above, there is the topic of jamming. While there is much debate on the probability of an EMA becoming jammed, the probability on an EHA jamming will be significantly lower. In this area the EMA may be judged sufficiently reliable for many, even manned, applications, but since the EHA uses the same piston and cylinder designs that have flown for decades the numbers are in its favor.

• Where else are EHAs used?

EHAs are starting to show up in a number of industrial applications were the ease of integration is a driving force. In one application, the hydraulic power needed to be transmitted through a rotary joint. Switching to an EHA made the integration much simpler since the power supplied through the rotary joint was electric and not hydraulic. This was a special case but in many industrial or commercial applications EHAs provide the right mix of hydraulic power in a self-contained unit that does not require infrastructure or a lot of maintenance. In many machine tools EHAs are attractive for their durability and compactness. Since the actuators only consume power when the systems demands it, the hydraulic oil is not constantly being worked and the need for thermal management and replacement of oil and filters is eliminated. Also, the EHAs can deliver higher forces for longer life spans without replacement of costly rotary to linear screw mechanisms like ball or roller screws.

• What should be considered when evaluating an EHA solution?

If the advantages of integration or redundancy make an EHA solution look attractive, the main performance consideration that should be reviewed is the application’s duty cycle. Since electric actuators, including EHAs and EMAs, require torque from the electric motor to maintain a load, any duty cycles that requires holding a significant load may create a thermal problem for the motor or controller due to the I2R losses. An example of this would be an aileron on a wing. Since the aileron surface is part of the wing and is subjected to a constant lifting load during flight, the sizing of the EHAs electric motor is driven by the requirement to hold the lifting load for the duration of the flight at a current level that the motor and controller can sustain. This is not typically a consideration in a conventional hydraulic system since the actuator can hold a load without expending any significant amount of energy. Another aspect to consider when reviewing an application is the ambient temperature that the EHA will operate in. If the ambient temperature is extreme, care should be taken in reviewing the hydraulic fluid properties over that temperature range. In applications where the environment can be very cold and the demand on the EHA is light, mitigating control schemes may need to be employed to maintain the fluid temperature such that the viscosity is within and acceptable range. Conversely, due to the small volume of fluid within the EHA, in an application with a high ambient temperature and a continuous work load, the EHA may need a method to dissipate the heat that will build up within the fluid.

• What advancements is Moog making with EHAs for future applications?

In the space launch business we are looking to produce higher performance in smaller packages to reduce weight and volume. The main focus in this effort is advancing the pump technology. One current effort is looking to improve the torque efficiency and raise the velocity limit of an existing pump to get more flow with less torque. Other efforts are looking at different pump technologies, new materials and simplified systems.

Dual Motor-Pump Module, Flow Summed EHA 70,000 lb Stall Load / 42 Horsepower

Dual Motor-Pump Module, Flow Summed EHA 70,000 lb Stall Load / 42 Horsepower

Typical Hydraulic System Maintenance

Typical Hydraulic System Maintenance