With today’s escalating energy costs, the manufacturers of Dual Fuel Gas Turbines are constantly looking for ways to improve efficiency, and meet ever more stringent emissions requirements. Key to these needs is the Liquid Fuel Metering function, which directly controls the supply of liquid fuel to the turbine burners (e.g. comparable to diesel). Moog has been working on fuel metering technology to improve performance for over 20 years. Before we examine Moog’s latest development, let’s take a look at how this latest solution has evolved.

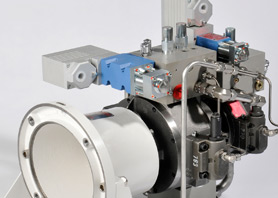

Moog Fuel Metering Manifold

Established Technology

The established Moog fuel metering solution comprises a custom made manifold system, which used in conjunction with a fixed displacement pump, controls the fuel flow to a single or multi stage burner system. The key control elements of the system are high accuracy Moog Direct Drive Valves (DDVs), controlling the flow to the burners, whilst hydro-mechanical valves regulate the spilling of surplus fuel back to the reservoir.

The integration of all the control devices into a single pre-tested, calibrated manifold, provides a compact solution completely eliminating interconnecting pipe-work, giving improved reliability.

While this approach gives extremely high accuracy of fuel metering (1% of maximum), it has the inherent characteristic of generating heat in the spilled fuel with a consequential energy loss.

The New Moog RKP Pump Approach

This new approach combines a simplified fuel metering manifold and variable displacement pump in a single assembly. The accurate Moog DDV control elements are retained, but there is no requirement to spill excess fuel as the intelligent pump delivers only the fuel demanded by the system.

Generally tandem variable displacement pumps are used for independently supplying the pilot and the main burner. This eliminates any unwanted interaction between fuel streams associated with the more established single pump solution.

The custom designed Moog RKP pump incorporates a hydro-mechanical compensator which senses the burner pressure and delivers only the exact flow required.

Moog RKP Fuel Metering

An example of the in-house acceptance test flow versus command demonstrating the exceptional repeatability.

E114 RKP Flow Plots

A key feature of this compensator is its ability to respond very quickly to changes in fuel requirements, allowing it to respond to sudden changes in turbine power demand.

This technology has already been applied to turbines of power levels of up to 15 MW corresponding to fuel flow rates of up to 100 lpm (28 gpm) at 100 bar (1450 psi). Typical fuel types that have been accommodated include diesel and diesel derivatives. The system is ATEX certified for use in Group 2, Category 3 hazardous areas.

Key Customer Benefits

The benefits of the Moog RKP Fuel Metering System for a Gas Turbine user are:

- Improved reliability due to integrated construction

- Reduced fuel consumption due to improved fuel metering accuracy

- Reduced energy costs due to improved pumping efficiency

- Simplified installation due to integrated construction

- Modular range with single standardised package

- Improved start-up performance due to independent fuel metering streams

The new metering system is now fully developed for production, and is currently being used by a major Power Generation OEM for five sizes of turbine.

Future (and planned) enhancements include increasing the size of the pumps and further optimization of the manifold to accommodate larger flows required by medium sized turbines.

Authors

Geoff Carson, Sales Engineer, Moog Tewkesbury

Geoff Carson is a Sales Engineer at Moog in Tewkesbury. Geoff recently moved from engineering where he focused on pumps in the Power Generation market. This role included the implementation of the RKP-II in relation to fuel metering. Geoff has been with Moog for 15 years.

Martin S. Jones, Market Manager for Niche and Emerging Markets in Europe

Martin S. Jones is responsible for the Motorsport business around the world and is also the Market Manager for Niche and Emerging Markets in Europe. He has worked for Moog for 30 years in sales and applications engineering for a range of industries including mobile equipment, marine and offshore, blow molding and rolling mills. He studied Physics and Economics at the University of East Anglia.