In this article:

- Pitch system failure accounts for 23% of all wind turbine downtime

- Advances in pitch system design can greatly improve LCoE (Levelized Cost of Energy)

- Fewer components, consolidated electronics and less required maintenance are the hallmarks of Moog’s next-generation pitch control system

- Moog's new Pitch Control System improves wind turbine reliability by up to 3x over existing systems

Pitch systems keep a turbine running and ensure the safety of the turbine in the event of high winds or catastrophic events. The pitch control system, mounted inside the wind turbine’s hub, monitors and adjusts the inclination angle of the rotor blades and thus controls the rotation speed of the blades. Although these systems play an outsized role, they account for less than 3% of a wind farm’s capital expenses (CapEx).

According to a 2011 ReliaWind research report, pitch system failures account for 23% of all downtime in wind turbines. This is more than any other component or system of the turbine. The ReliaWind report goes on to note that pitch systems tallied the highest percentage of all component failures in wind turbines at more than 21%.

Benchmarking Reliability

When it comes to improving reliability in wind turbines, the pitch system is a critical component. One of the challenges faced by the wind industry lies in understanding where efforts to improve component reliability will translate into the greatest return on investment. Most of the research done in the past on this subject has focused on mechanical and electrical system level analysis – providing very little depth in terms of failure analysis at the component level and its impact on cost of energy. Earlier this year, Moog partnered with DNV GL, an international certification body and provider of technical assessments, to quantify the:

- impact of pitch system reliability on turbine failure rate, and

- improvement in Levelized Cost of Energy (LCoE) due to advances in pitch system reliability through innovative design.

LCoE measures the net cost to install and operate a wind turbine against expected energy output over the course of the turbine’s lifetime (incentives excluded). Moog and DNV GL collected data from 69 projects totaling 5.3 GW of capacity across four million turbine days for wind turbines located in North America, Europe and China. The turbines ranged in size from 1.5 MW to 3 MW.

The Moog-DNV GL benchmarking study confirms that pitch systems (whether electric or hydraulic) have a high rate of failure and significant effect on turbine reliability, downtime, operating expenses and LCoE.

Improving Pitch System Reliability through Innovative Design

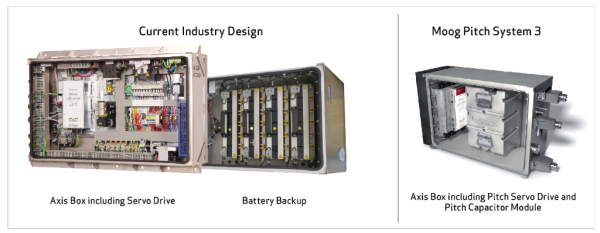

As part of the study, DNV GL’s research team analyzed a number of wind turbine makers’ electromechanical (EM) and electrohydraulic (EH) pitch systems operating in the field as well as a newly designed next-generation pitch system from Moog, known as the Moog Pitch System 3.

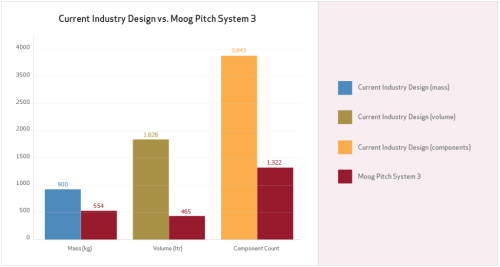

A typical pitch system used throughout the industry today consists of roughly 3,000 to 4,000 sub-components and has a system reliability of approximately 5,700 hours. Field data collected for the study is a representative sample of these designs.

“In wind energy, improving pitch system reliability and maintainability with an innovative design lowers the cost of energy for wind farms.”

The Moog Pitch System 3, developed and released in 2016, consists of 66% fewer parts than the pitch systems installed on most turbines today.

The benchmarking study shows that turbine reliability can be improved significantly by using Moog’s next-generation pitch control system. This is largely because current industry designs incorporate components manufactured for general-purpose industrial applications with limited customization for wind turbines. Some of the opportunities for improving on these designs include consolidation of functions and designing electronics specifically for the wind turbine hub environment rather than wiring off-the-shelf DIN-rail components. Another opportunity for design improvement is through the use of ultra-capacitors, instead of batteries, to eliminate backup power failures and minimize periodic maintenance.

The Moog Pitch System 3 capitalizes on these opportunities including, pluggable/integrated electronics for the system’s drives, AC servo motor technology and advances in ultra-capacitor design. With permanent magnet synchronous motor technology (i.e., brushless, no fans for cooling), Moog’s engineers improved pitch system motor reliability and reduced periodic maintenance compared to DC motors currently used by the wind turbine OEMs. These improvements have helped the Moog Pitch System 3 set a new benchmark in pitch system reliability.

In fact, the new Moog Pitch System 3 improves wind turbine reliability by up to three times over current industry designs.

Improving the reliability of the pitch system directly affects the turbine reliability by mitigating downtime. And reducing maintenance, in turn, lowers LCoE. The DNV GL LCoE model also shows that the Moog Pitch System 3 can save up to $1.70 / MWh for a typical 3.0 MW turbine.

An optimized pitch system with pluggable/integrated electronics for the system's drives, AC servo motor technology, and advances in ultra-capacitor design—along with additional enhancements—has significantly improved pitch system motor reliability and reduced periodic maintenance.

For more background on how pitch system design can impact your LCoE (Levelized Cost of Energy), download the full white paper.

Author

Mr. Prasad Padman, an instrumentation and control engineer with a masters degree in finance and marketing, has been with Moog for eight years in various roles. He is currently responsible for developing needs for next-generation motion control solutions.