Electrohydraulic Servo Actuators

Moog has vast experience developing electrohydraulic actuators for some of the world’s most demanding applications. OEM and end-user customers who need hydraulic-powered solutions for their high performance motion control systems rely on Moog for the ultimate in reliability and performance.

Explore our standard configuration models which use the latest hydraulic technology for performance, efficiency, and long-life capabilities. For customers who require a custom solution, our application engineers are available to design actuators built to your exact system needs.

Moog hydraulic single-ended servo actuators are most commonly used for structural test and simulation applications. Additional solutions can include a variety of industrial production applications, including material handling facilities.

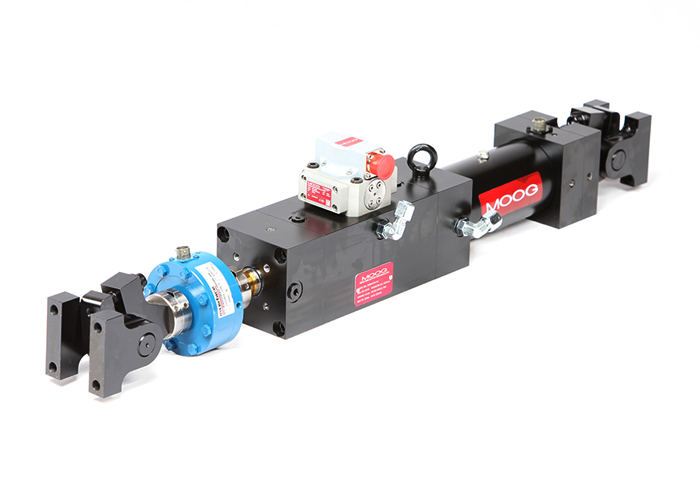

Moog's Hydraulic Double-Ended Servo Actuators feature oil-cooled polymer bearings for improved side load capacity compared to other actuation technologies. These fatigue rated actuators deliver high performance and flexibility for a range of single and multi-axis applications in automotive testing, structural testing, fatigue testing and vibration testing systems.

Moog's Hydraulic Low-Force Servo Actuators are double-ended components mostly used for test systems. The design allows for equal force and tension on both sides up to 10 kN (2.2 kip) These fatigue rated actuators deliver high performance and flexibility for a range of single and multi-axis applications for material, structural and component testing.

Legacy products refer to Moog's end-of-life offerings that are not to be used for new projects.

Moog Application Engineers can meet your special performance needs: