Launch Vehicle and Missile Propulsion

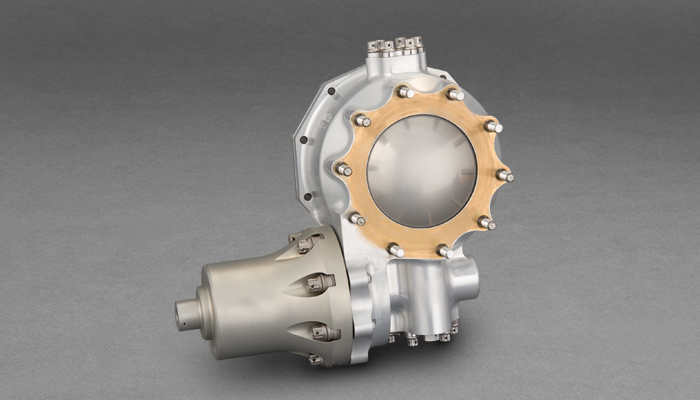

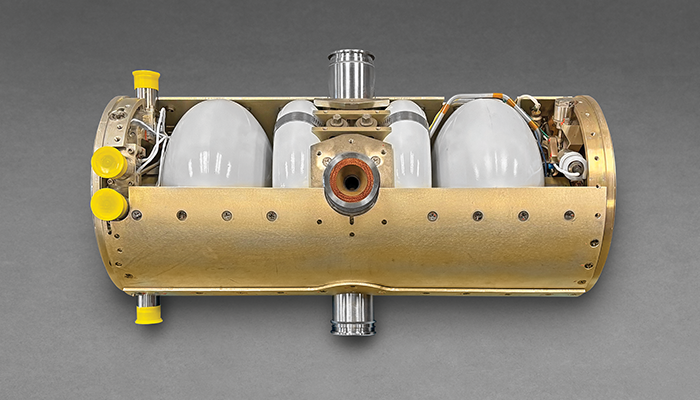

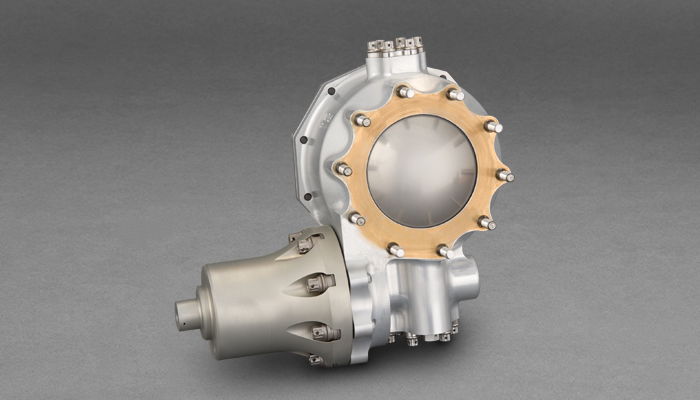

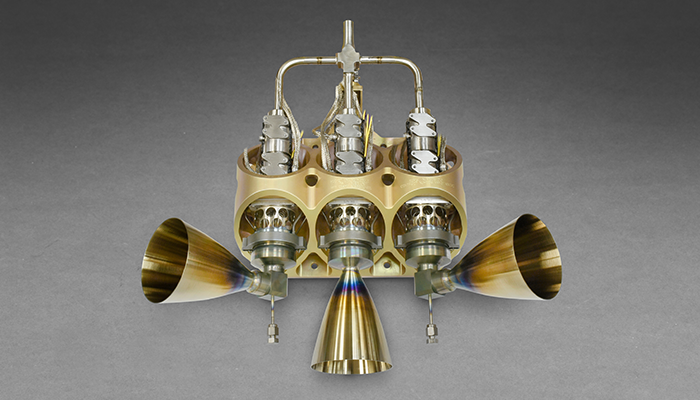

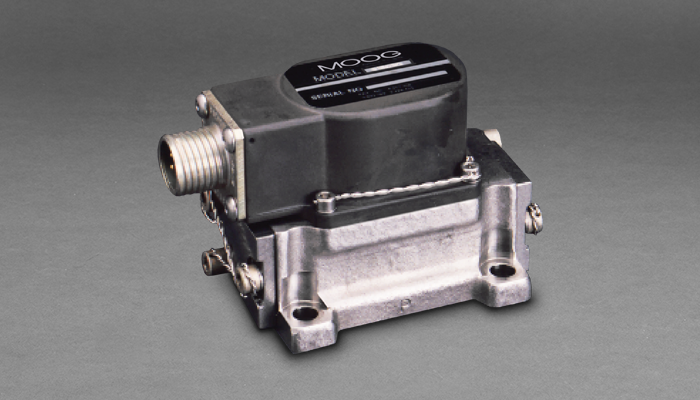

Injector Valves

Moog’s injector valves are pilot operated, normally closed SIET valves used in support of missile or spacecraft engine bi-propellant applications.