In this article:

- Moog customers are increasingly exploring electric and hybrid motion control technologies

- Moog’s Prototyping and Production Center in Germany yields innovative, modular designs

- Three keys to selecting the right partner: market knowledge, application expertise and a robust product portfolio

In many cases, electric technology represents the superior solution for industrial applications, providing important benefits such as environmental cleanliness, lower noise, less energy consumption and high efficiency. As customers seek these electric-based motion control solutions for key industrial applications, a key consideration is choosing the right technology partner. First and foremost, this partner should understand electric technologies and how they work in the application. Yet a vendor that has a solid foundation in hydraulics and hybrid technologies as well as electric is critical. After all, the vendor providing an unbiased assessment of the best technology for your machine—electric, hydraulic or hybrid technology—should be based on the exact needs of the application.

While many companies associate Moog with hydraulic technology, today, approximately 40% of Moog Industrial Group’s systems are based on electro-mechanical motion control technology. As an experienced designer and manufacturer of electric motion control products such as servo motors, servo actuators and controllers, Moog brings the advantage of the ability to easily tailor these products to meet specific machine requirements. Most importantly, Moog brings the same high performance and reliability to electric motion control solutions that have made the company famous for hydraulic technologies.

Below are several brief case studies concerning electric solutions that Moog has developed to help customers meet unique application and machine requirements.

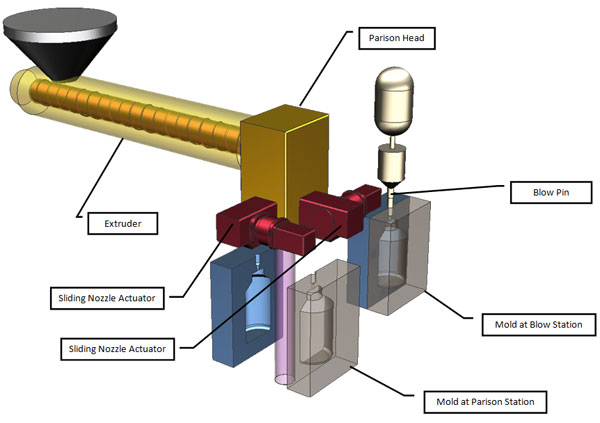

Moog electro mechanical actuator for plastics machinery

One of the biggest European producers of customized blow molding machines approached Moog to help develop a next generation machine using full electric motion control technology for the extrusion unit. For asymmetric parts which do not have a uniform round shape, the machine needs to adjust the wall thickness of the extruded tube. Formerly, the adjustment of the eccentricity was done by hydraulic servo actuators. However, the customer wanted to switch over to an electromechanical actuator to perform this function.

The Moog Short Stroke Actuator is a precise, compact, robust, low inertia electro mechanical actuator capable of performing highly dynamic position control and force control. This solution maintains high efficiency during positioning even when exposed to high static forces. It is designed with robust construction and lifetime lubrication for maintenance-free operation. A low friction technology concept enables reliable position control and force control. By using this solution, the customer was able to meet its particular needs in terms of accuracy, robustness and compactness. The electric actuator is an easy substitution for a hydraulic actuator. It is the same form factor but it offers the benefits of the elimination of oil as a potential source of contamination, improved energy consumption, increased productivity and less maintenance.

Moog concept for blow molding machine

Read more technical information and specifications on the Moog Short Stroke Actuator.

Shaping the future of motion control: Electro-hydrostatic actuation

Customers seeking to incorporate new motion control technologies should actually focus on the outcome rather than on a preferred technology. This ensures a productive and efficient machine application rather than "change for the sake of change." As a motion control specialist using electric or hydraulic technologies, Moog engineers have practically no boundaries and offer "technology neutral solutions" that are dependent on the customer’s application needs.

Energy efficient and compact:

Moog Electro-Hydrostatic

Actuator

Moog engineers recently developed a new concept for electro hydrostatic actuators based on both technologies, which is suitable for many applications. From our perspective, this technology can offer considerable advantages but the suitability and benefits of the technology depends largely on the application.

For example, in the power generation market that uses gas and steam turbines, this technology enables precise control of vane gates, fuel flow, and blow off valves. The fail safe function returns the process valve to a closed position by using a hydraulic accumulator or by a mechanical spring with an appropriate hydraulic circuit. In solar power systems, the panels of a solar thermal plant need to be directed towards the sun. In this application, a motion control system using electro-hydrostatic actuation is more efficient, compact, environmentally-friendly and easier to maintain than a hydraulic system.

Three keys to selecting the right partner

Market Knowledge—How long has the potential partner been designing solutions in a particular market or industry? What customer success stories do they offer?

Application expertise—How experienced in a specific discipline are the engineers who would facilitate your solution? How does your potential partner manage complex cost- or time-sensitive projects? What types of simulation tools enable the engineering team to verify the expected performance of a sub-system or machine function?

Product portfolio—Does the provider offer a robust line of proven motion control components that can be integrated for leading-edge solutions? Are they willing to tailor these components to provide performance that meets your unique application needs? Is their service and support network capable of handling your requirements anywhere in the world?

Building the infrastructure for designing efficient electric systems for our customers' applications

Moog's new Production & Prototyping Center in Böblingen, near Stuttgart, Germany.

Prototyping is a critical step for customers transitioning to electric technologies. It is essential that all performance parameters are thoroughly examined, tested and proven before the actual solution is incorporated in the customer’s environment. Moog recently invested in a new 18,300 ft2 (1670 m2) production and prototyping center in Germany for electric applications. This building accommodates a large, specialized engineering team that develops, tests and produces servo motors, actuators, servo drives and other electric motion control technology used to build systems tailored to the needs of customer applications.

This facility enables the development of innovative, modular designs that meet the unique requirements of our customers. When a fast prototyping and testing capability and an extensive approved supplier network is combined with a skilled, experienced and trained engineering team that is committed to working in close cooperation with the customer, the result is sure to meet customer expectations and deliver high performance in a given application. Today, global machine designers work with the Moog prototyping team on the most complex projects, requiring very specific application knowledge.

This center is where innovative hardware and system designs are born. Moog engineers design and build flexible prototypes that can later be produced at any Moog location in the world including 26 countries in Asia-Pacific, the Americas or Europe. The test facilities are able to run 24/7 testing important to determine reliability of products and systems such as testing motor bearings, gearboxes or special cooling arrangements.

Summary

Moog has collaborative sales engineers experienced in understanding the customer’s needs who work with our business development and system engineering team to define the optimal solution. Our product design team is capable of developing the right products and solutions for the exact performance and system requirements of our customers. Whether the solution is electric, hydraulic or both (such as electro-hydrostatic technology), you can count on the extensive, proven experience of the Moog team.

Most engineers know Moog’s history as experts in hydraulic motion control technology, but in the past 20 years, this has expanded to include electric solutions as well. Moog has become a technology leader in electric motion control solutions for applications such as flight simulation motion bases, medical simulation systems (based on haptic technology), pitch control systems for wind turbines, actuators for gas and steam turbines, automotive and aerospace test rigs, driving simulators, and many more. Moog also designs and manufactures many electric motion control products such as high-force actuators, highly dynamic servo motors, high-powered servo drives, motion controllers and software for diverse applications and markets.

If you’re interested in learning more about Moog’s approach to electric motion control technologies, simply download your free copy of our latest whitepaper on one of Moog’s most demanding applications: providing actuation solutions for downhole drilling. Regardless of your industry, this whitepaper will give you some insight into how our engineers work with customers to provide efficient and productive solutions in some of the world's most hazardous operating environments.

Author

Ari Almqvist is the European Manager of the Control Solutions Department for Moog and a member of the European Management Team. Control Solutions encompass market development, systems and applications engineering, and project management. Since joining Moog in 1988, Ari has many strategic roles including General Manager of Moog FCS in The Netherlands, Defence Control Manager Europe, Manager of Electric Systems in Central Europe, Product Line Manager of Systems Electronics, System Engineering Manager in Moog Germany and Area Manager of Moog Finland. He has a Bachelor of Science in Automotive Engineering from Helsinki Technical University of Applied Science and an MBA from Alto University in Helsinki, Finland.